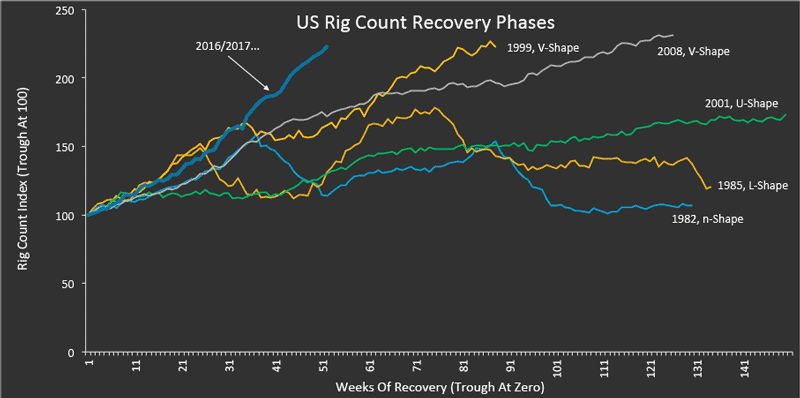

In June 2016, activity in the U.S. onshore oilfield hit rock bottom. The drilling recovery that has played out since then is the sharpest in modern oilfield history. The number of active U.S. land drilling rigs has increased from 400 at the bottom to 900 today.

This is quite a remarkable accomplishment as oil prices have only recovered to about half of their prior highs ($50 per barrel as of June 2017 vs. a peak of just over $100).

To make drilling these new wells economic at today’s commodity price levels, producers are employing the following big picture strategies:

- High-grading. Most of the rigs that have returned to work are drilling wells in the highly prolific oil formations of Texas and Oklahoma. Because oil prices remain low, Exploration and Production (E&P)companies have consolidated their drilling activity in the best areas of the best shale plays.

- Multi-horizontal well pad drilling. Essentially, this concept involves drilling groups of horizontal wells very close together to keep costs down and fully drain the reserves they are targeting. Sometimes wells are drilled as close as 250 feet apart. The spacing has been shrinking as E&P companies look to maximize drilling inventory in the best areas.

- Hydraulic fracturing. After the wells are drilled, they are stimulated with a process known as hydraulic fracturing (often referred to as fracking by the press) to increase production. This process involves pumping water and sand under very high pressure down into the well to rubbilize the rock and create fractures that draw “tight oil” into the well-bore and up to the surface.

With the industry running full speed ahead on these strategies, we are beginning to see some cracks in the wall. The first evidence is now emerging that the combination of these tactics has finite physical boundaries.

Drill too many wells, too close together and you get something the industry calls “frac hits.” Today, the oil industry is more worried about this problem than ever before.

What is a Frac Hit?

This is a term the oil industry has coined for interference between wells. When new wells are hydraulically fractured, older adjacent wells are placed at risk of premature declines in their production. “Inter-well communication” between wells during hydraulic fracturing treatments can be violent, in some cases strong enough to damage the older wells. Some wells never recover from the damage done to their equipment and the reservoirs they are tapping.[3]

Interference from a new fracturing treatment can cause extensive problems for older wells including: expensive downtime as offset wells have to be shut down while the fracturing treatment nearby is conducted, remediation after the fracturing treatment and lost productivity in older wells. In addition to damage done when the stimulation treatment is being pumped, these older wells can lose productivity as the new ones compete with them to drain the same resources.[3]

As horizontal well counts grow, producers are being forced to navigate a difficult maze of old wells as they plan new ones. To protect existing wells, operators who are working in the same area have to open new channels of communication to notify each other in advance of fracturing treatments.

Frac Hits are occurring with increasing frequency

In the past, frac hits were a mostly back-office problem – largely compartmentalized in the completions engineering department. But today, this problem is escalating up the ladder and into the C-suite as companies have had their results impacted more often by frac hits.

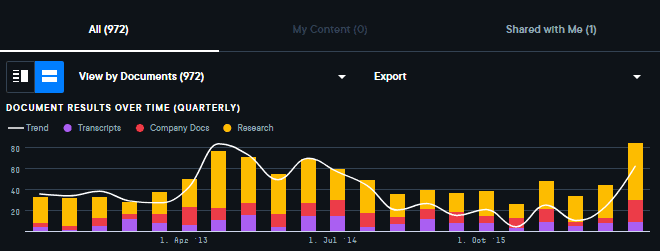

To gauge the industry’s interest in this topic, I ran a keyword search on AlphaSense for frac interference OR frac communication OR frac hit OR frac hits. You can clearly see in the search trend chart below how concerns around this potential bottleneck have begun to escalate.

AlphaSense Smart Synonyms automatically expand your searches to include related keywords.

This issue presents not only a risk to the viability of the ongoing drilling recovery, but also to the industry’s long-term prospects. This is a potential threat to the thousands of wells in drilling inventory that the industry is counting on to grow production and replace declines.

The E&P industry is learning how to respond to the problem

Using AlphaSense, I ran a search for frac hit concerns and used the Sectors / Industries Filter to show me results just across the E&P company universe this month, to better understand how management teams are responding to this growing problem.

During 1Q17 earnings season, many E&P management teams talked about how frac hits are impacting their drilling programs and how they are mitigating the impact. We expect this will continue to occupy more time on conference calls going forward.

Here are a few of the most notable excerpts we identified:

1. Newfield Exploration: “Our Team Has Been Challenged, We’re Investing in Learning, More to Come Later This Year” (May 3)

“On the first issue on interference, since most all of the wells up until the course of the last 12 months or so were single wells on individual DSUs, we know that they’re unbounded. So that’s one of the phrases that we used consistently. I think our teams have been careful to wrap the data accordingly. As we move wells closer, there’s — you get the price element on the spacing equation. You’ve got the lateral offset equation on that. You got the vertical offset. And then in and amongst that, you’ve got what’s the right size job that you start moving these wells in and packing them in closer. We’re investing in learning today. Our team has been challenged, and I think we see it in our peers in the play as well to go invest in the learnings that we need to optimize development. So our intent is to test the plays where the constructive interference becomes suboptimal, and then we’ll all back up to whatever the right solution is at that time. But I think that that’s why we stress the need for time, and time is part of the equation figuring this out. So we’ll have that information later this year. There could ultimately be trade offs on size of the job and well spacing, but what we’re going to be solving for is maximizing net present value. And I think that’s what most of the companies that are in development mode are going to be focused on, and we’ll give you what we think the solution is as that data comes available.”

2. Marathon’s Completion Recipe Had to be Tweaked After Communication During Yost Infill (May 5)

“We had a really strong parent well at the Yost and also, from our subsurface-integrated workflow, noted some higher natural-fracture intensity around that parent well, and so it’s fair to say that we did see some communication impacts as we came back in and infilled that. We’ll take those learnings, and have taken those learnings into the Hansens. And we do think there’s optimization that can be done, and we’ll be changing the completion recipe a little bit as well as the gap-out test that we’re doing on that location. So very early days, we’re certainly encouraged by the early results, kind of confirming the base case but like any of these programs that you’re in early days, there will be some optimization to come.”

3. Legacy Reserves LP is Doing Batch Completions Partly Because of Frac Hits (May 4)

“We continue our two-rig Permian program… To increase the efficiency of our stimulation, we are completing our horizontal wells using a batch completion of up to 6 wells at a time. This approach maximizes recoveries by minimizing pressure sinks and reducing well communication… We went to the batch completions just because we think that’s better, from a well-to-well basis, as we see frac interference, getting those things competing with each other.”

4. Energen is Actively Managing the Risk, Shut-ins Reflected in Budget (May 5)

“Well, the thing we always get faced with and we try to anticipate as best we can and sometimes get surprised by it is, obviously, if you’ve got an offset operator doing a completion, you’re going to have to shut your well in. And we try to factor that in our budget as best we can, but that’s just a fact of life, and we do the same thing to others. When we come along, we drill a well next to them, they’re going to have to shut it in during that process. And so that’s something we try to account for when we do the budget as best we can… We know where people are drilling. I mean, you always know that the well’s being drilled before the completion comes… there’s no long-term planning on when that frac is coming that might bash you. But we do have communication with all of the offset operators as well as lead communicators. There’s several-week notice, and you can prepare for it. And as a rule, it’s according to the distance, but we will shut in or we will take measures to minimize the impact on us. However, a nice thing about our acreage is that we’re pretty blocky. I mean, we have edges. But a lot of our acreage is protected where we offset ourselves, and that’s a nice thing. And so we will have some exposure. We don’t see it as being a major concern for us. Just the remainder of this year, though.”

It may soon be time to ask a question that was unthinkable just a few years ago: Is the U.S. oil industry in danger of running out of locations to drill sooner than they expect?

We acknowledge that actually running out of drilling inventory is very different than revising, “the best inventory” or taking a productivity/cost hit to overcome the problem. The latter options being the most likely outcomes in the medium-term. But none-the-less, this is an important topic that the industry needs to address.

We’ll be using AlphaSense to stay alerted on the industry’s response to the frac hit threat using their automated email alerts and watch lists in the quarters ahead.

Joseph Triepke is the founder of InfillThinking.com, an independent research firm delivering oilfield market intelligence to subscribers. Prior to launching Infill Thinking, Joseph was an equity research analyst covering the energy industry for large buy-side and sell-side institutions.